-

Condensate Water Recovery Device

-

Reverse Osmosis Equipment

-

Fully Automatic Water Softener

-

Industrial Sand Filter

-

Water Supply Equipment

-

Chemical Dosing Device

-

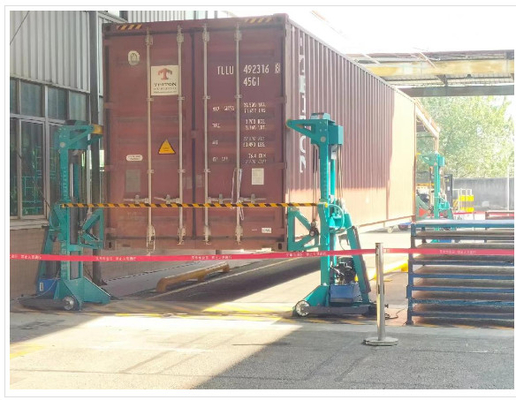

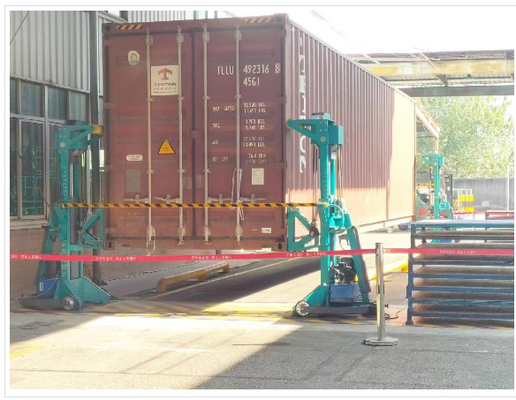

Container Flipper

-

Container Loading and Unloading Machine

-

Truck Flipper

-

Electric Transfer Cart

-

Electronic Weighbridge

-

Mobile Loading Dock Ramp

-

Air Compressor Heat Recovery

-

Water Treatment Accessories

Customizable Carbon Steel Flip Angle Combilift Container Loader With 0-180 Degrees Flip Capacity

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | It Has Gained Market Recognition For Its Flexibility, Mobility, And Energy-saving Performance, Improving Operational Efficiency And Reducing Operating Costs. | Flip Angle | 0-90 Degrees - 0-180 Degrees |

|---|---|---|---|

| Material | Carbon Steel | Type | Single Flip - Double Flip |

| Origin | Taian, Shandong | Customization | Customization Is Supported |

| Brand | Tonglida | ||

| Highlight | customizable container loader machine,customizable combilift container loader,steel container loader machine |

||

Product Description:

The primary function of the multi-functional container unloader is to load and unload containers, replacing the need for manual handling of large containers at ports or warehouses. This makes the use of external force equipment necessary, leading to the development of the container unloader - a compact and well-designed equipment that operates smoothly, reliably, and within an affordable price range.

One of the key features of the container unloader is its ease of operation, which allows for a single person to complete the loading and unloading process effortlessly. The equipment is also highly efficient, producing minimal noise and vibration, and it has become a popular and cost-effective option for many industries.

The container loading machine is another multifunctional equipment that offers efficiency for loading and unloading activities. This equipment is composed of a loading platform, a running subunit, an electrical control system, and more. To use the equipment, users load their cargo onto the platform using a forklift, raise it to a certain height, and push the cargo into the container. The entire process is completed quickly and effortlessly.

The container loading machine is powered by electricity, remotely controlled, and has several benefits, such as safety, speed, and ease of operation. The use of the equipment reduces the costs associated with manual handling of goods, making it an effective solution for the logistics industry, ports, and terminals.

Features:

The loading machine can be customized according to the specific needs of each customer, allowing for greater flexibility and ensuring that it is tailored to individual requirements. In addition to this, the machine is designed to operate smoothly and efficiently, minimizing any downtime and maximizing productivity.

When it comes to loading and unloading, this machine is a top performer, offering high levels of efficiency that can help to save time and increase throughput. It is built with productivity in mind, and has been optimized to provide the best possible performance in any industrial environment.

Finally, this loading machine is highly customizable, with the ability to be configured according to a range of different loading schemes. This means that it can be adapted to suit the specific needs of any application, making it a versatile and flexible choice for any industrial operation.

Technical Parameters:

The loading machine is an efficient solution to the traditional manual loading process, as it reduces safety hazards and completes the task in approximately 5 minutes. The machine operates smoothly, allowing for a high loading and unloading efficiency.

The loading machine has a large carrying capacity, which sets it apart from forklifts and manual labor. The machine platform can transport up to 30 tons of cargo at once, making it a feasible solution for handling heavy tasks.

The machine is equipped with a wireless remote control, which increases the loading and unloading process efficiency by 80%. This feature enables fast and remote operation, making the loading and unloading process much more manageable.

In situations where the loading machine is not in use, it can be moved aside, thanks to its electric towing system. This ensures that the work environment is not occupied.

Customized unloading solutions can be provided through the loading machine, depending on the type of cargo that needs to be unloaded. This ensures that the process is optimized to cater to the specific cargo needs, giving the device added versatility.

The loading machine has a compact design that requires only a 1cm margin on the left and right sides and 5cm on top. This design ensures that the utilization rate of containers can reach up to 99.9%, making it a highly efficient option for cargo transport.

Applications:

The container handling vehicles are equipped with powerful lifting, moving, and stacking capabilities, contributing to their high operational efficiency. This allows them to complete container loading, unloading, transportation, and stacking operations quickly and accurately, greatly improving logistics efficiency. Furthermore, this reduces the waiting and idle time for goods, making the entire logistics process smoother and more efficient.

The container handling vehicles are well-designed, with flexible and adaptable operations in narrow aisles and open yards. They can easily maneuver around obstacles and have excellent off-road capabilities and stability, enabling them to work reliably in diverse terrains and weather conditions. This ensures that the vehicles are always ready for any container handling task, no matter the environment or location.

Modern container handling vehicles are equipped with automation and intelligence technologies such as automatic recognition, positioning, grabbing, and placing. This reduces manual intervention, improves operation accuracy and efficiency, mitigates the risk of human errors, and reduces dependence on manual labor. This advanced technology allows for the streamlined management and organization of logistics processes.

Safety is a top priority in the design of container handling vehicles. These vehicles are equipped with various safety devices and warning systems to promptly detect and avoid safety hazards. Proper operation and maintenance ensure stability, reliability, and the safety of the operators. This ensures that the entire container handling process is safe and secure.

Container handling vehicles are a versatile solution that can be used in various logistics scenarios such as ports, terminals, yards, and warehouses. They can cater to different scales and types of container handling requirements, meeting the diverse needs of the logistics industry. With their wide-ranging applications, container handling vehicles are an essential component of the logistics industry.

Container handling vehicles provide reliable and efficient support for the development of the logistics industry. Their flexibility, automation, safety, and wide applicability make them an indispensable part of modern logistics. With their advanced capabilities and top safety standards, these vehicles are considered an essential tool for the logistics industry.